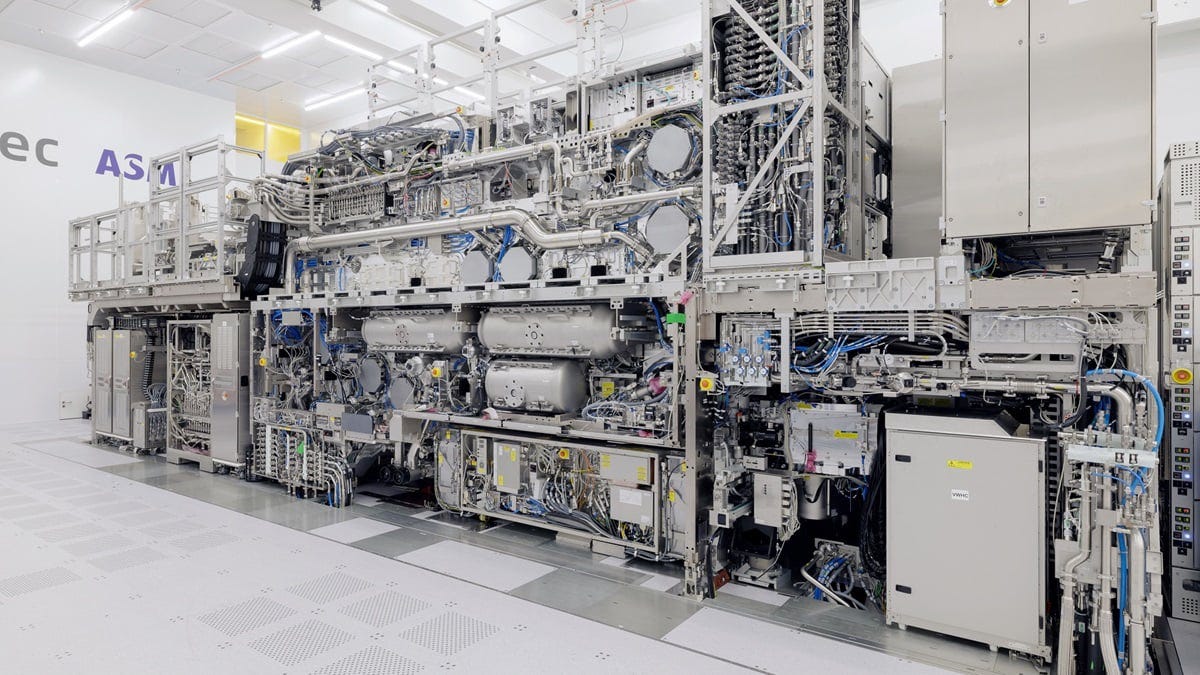

Did you know that nearly all the chips that are crucial to modern technology are printed by just a singular company? This company in question, Advanced Semiconductor Materials Lithography (ASML), is the only company in the world with the skills and the supply chain needed to build such a huge and complex machine that contains exactly 457,329 parts! This article will delve deep into the monopoly ASML has established and the fascinating technology its machines have.

Firstly, some background. ASML is a Dutch company founded in 1984 in the Netherlands. Ever since their founding, they have bet heavily on Extreme Ultraviolet (EUV) technology. After decades of research, they delivered their first machine capable of printing chips with EUV technology in 2017 and have since been growing their sales every year. They now have a monopoly on the world’s most valuable machine for printing chips.

Originally, before EUV machines, semiconductor chips were made using Deep Ultraviolet (DUV) Lithography. In essence, light would be shone through some special materials to print a particular pattern on a silicon wafer. However, natural light has its limitations, and in order to print chips with smaller and smaller gaps between the transistors, engineers had to introduce new workarounds with light that cost time and money to do. These limitations led to the birth of EUV technology.

EUV lithography uses a much shorter wavelength to print more precise images on the silicon wafer. However, this comes with many challenges. Producing EUV light involves pulverizing a small ball of tin with a laser. It is struck twice: first, to warm it up, and then second, to turn it into plasma with a temperature of 50 million degrees. This process is repeated 50,000 times per second to produce enough EUV light to create chips. The precision in these machines is mind-boggling. The ball of tin is exactly 30 millionths of a meter wide and the carbon dioxide based lasers needed to deliver massive amounts of power in precise quantities. Moreover, the mirrors needed to bend the EUV light once it has been created needs to be completely precise - ASML states that if those mirrors were scaled up to the size of Germany, the biggest imperfections would be a fraction of a millimeter. Ultimately, these EUV machines are some of the most complex and precise machines ever to be built in history.

The reason ASML is able to build such complex machines is due to their extensive supply chain. ASML only builds about ~15% of the necessary components for their machines and outsources the rest to other companies. This obviously comes with its drawbacks, but it is a necessary strategy to make a machine with so many components.

I am optimistic about ASML continuing to grow and perform well. They have an extraordinary monopoly on such a high value machine, and they will continue to make improvements over the years. Thank you for reading this article, and stay tuned for the next one!

Image Credits: Link

Note: Much of the information in this blog came from Chris Miller’s Chip War. I would highly recommend you to read this book.

Thanks for explaining such a complex technology in such simple terms!